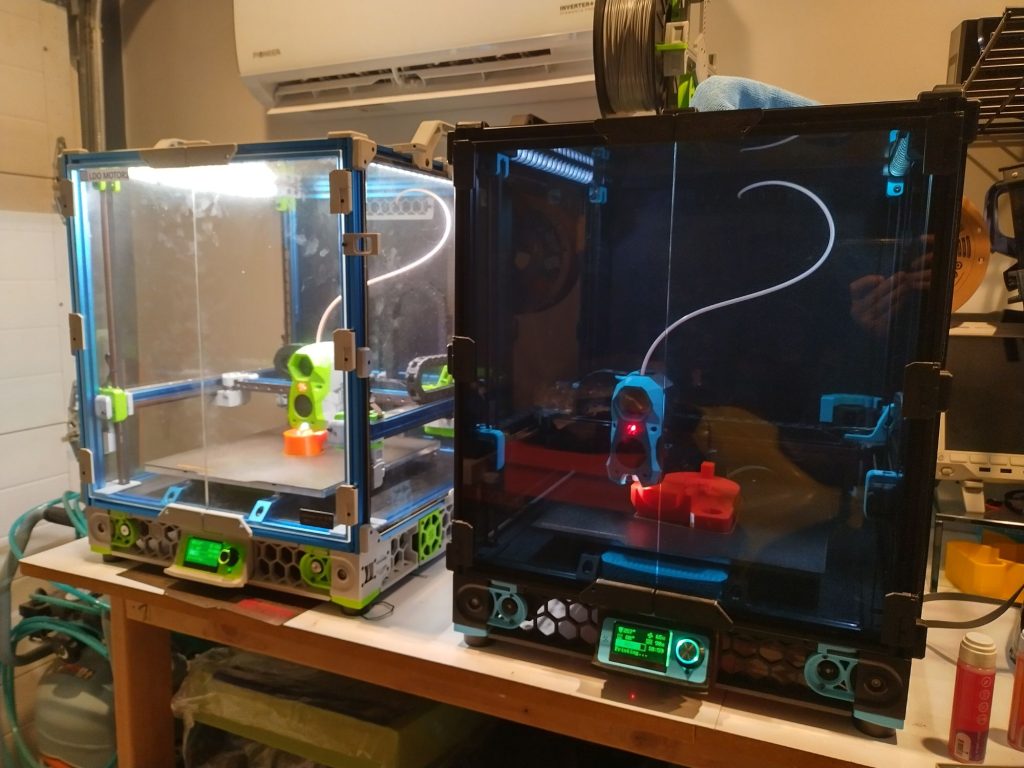

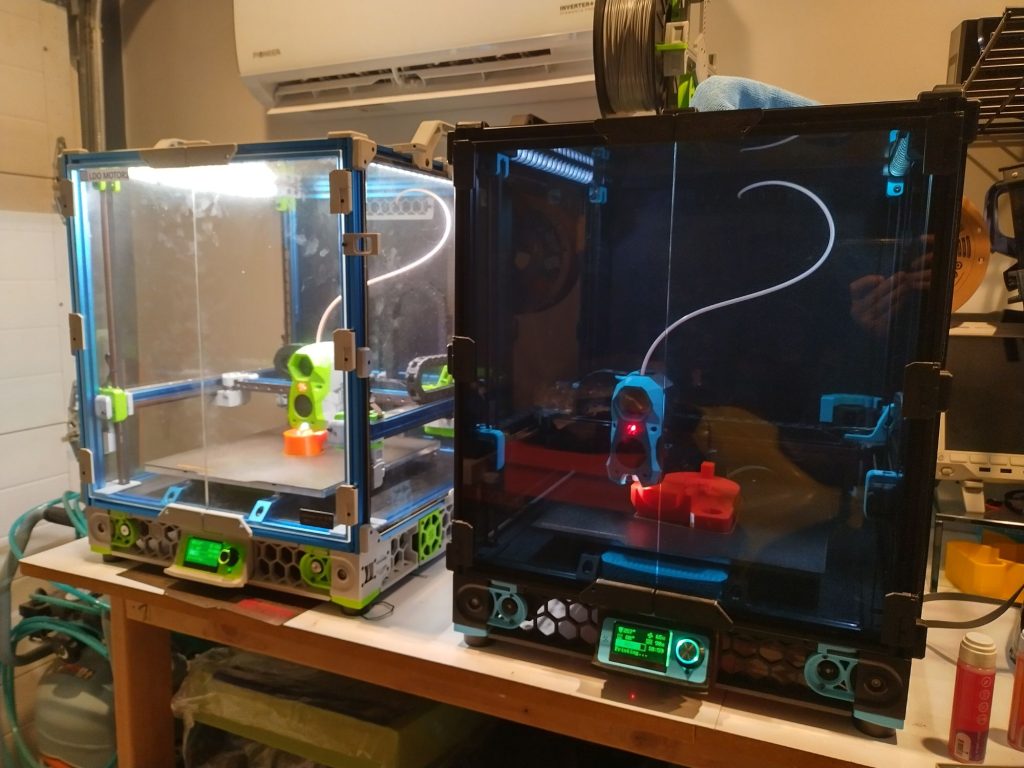

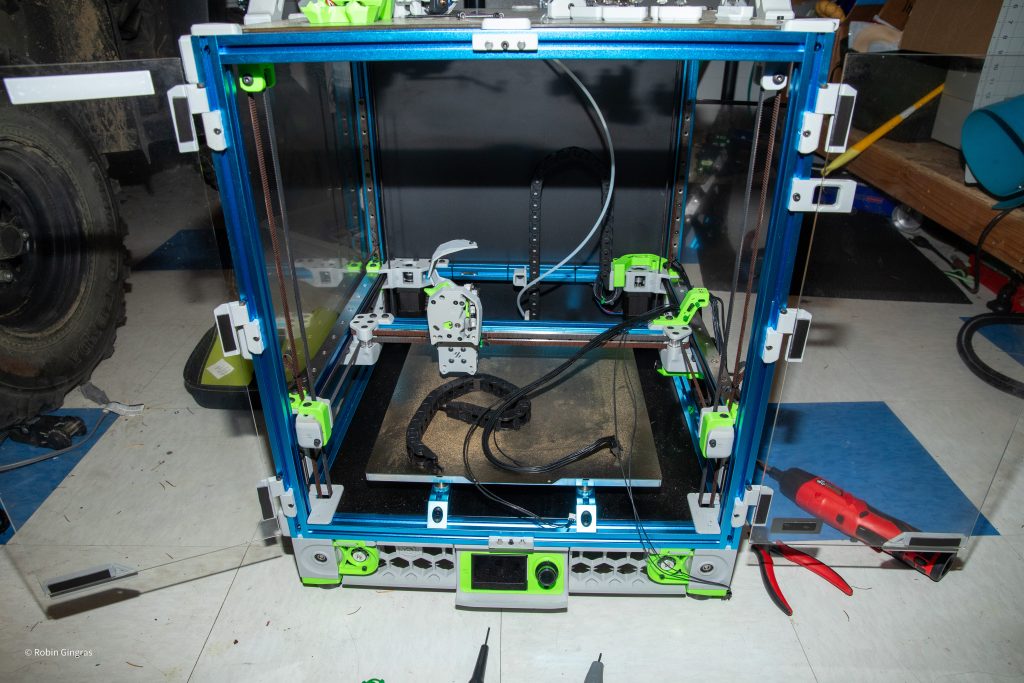

The printer is now printing!

Printing some robot arm parts…

The printer is now printing!

Printing some robot arm parts…

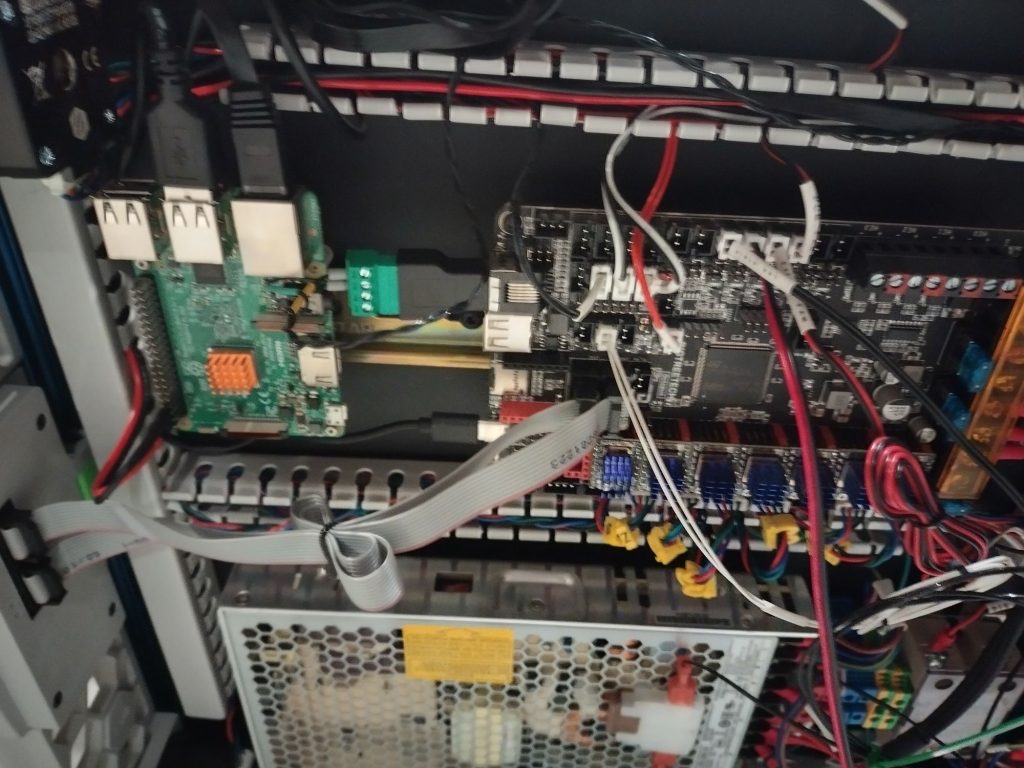

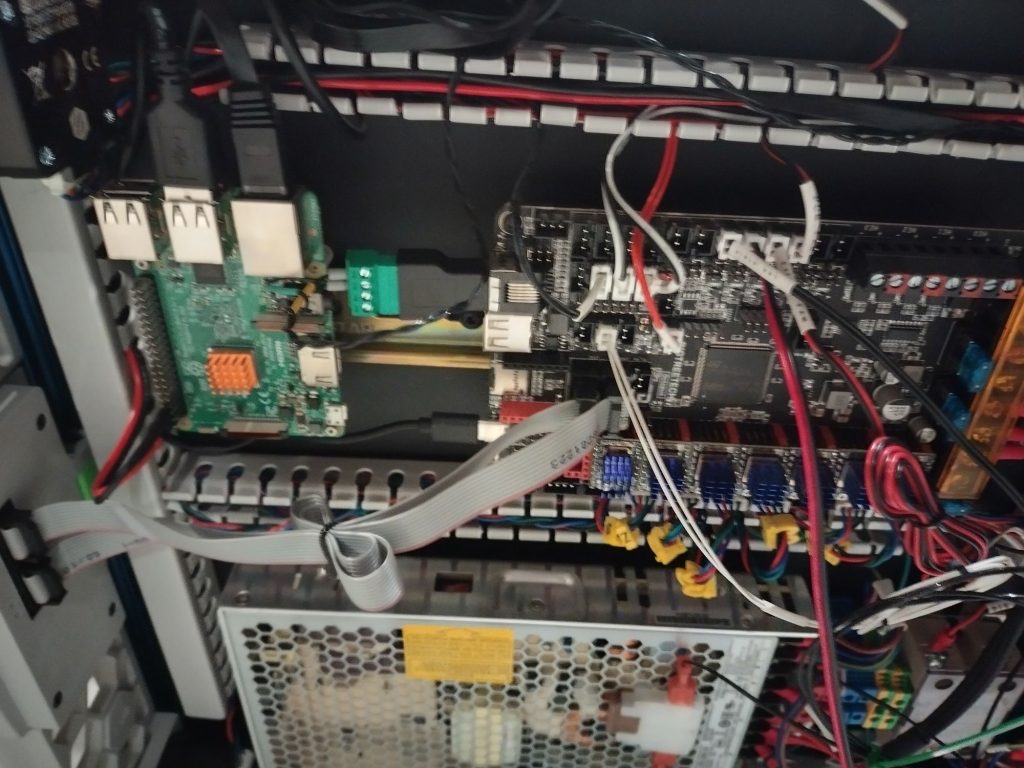

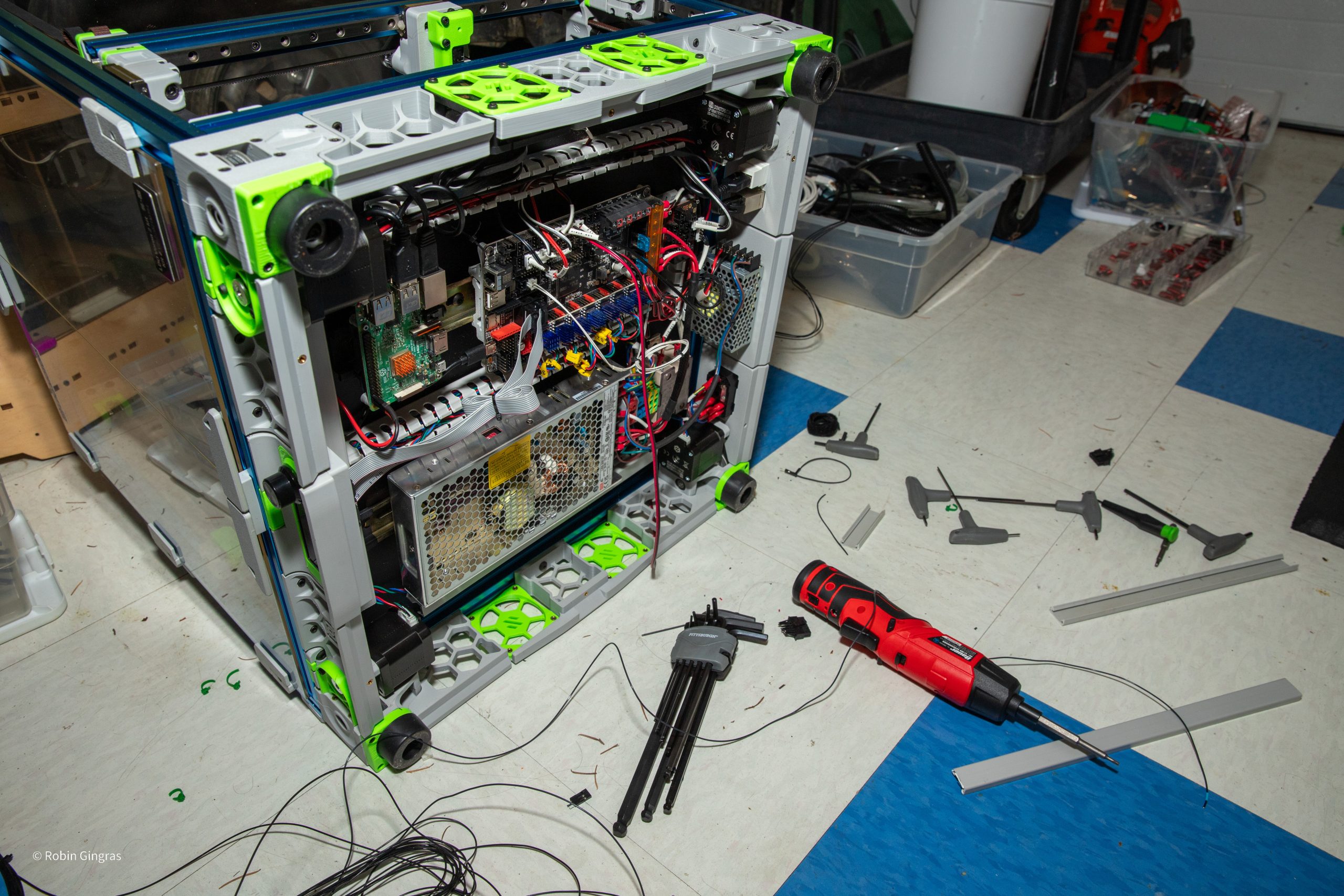

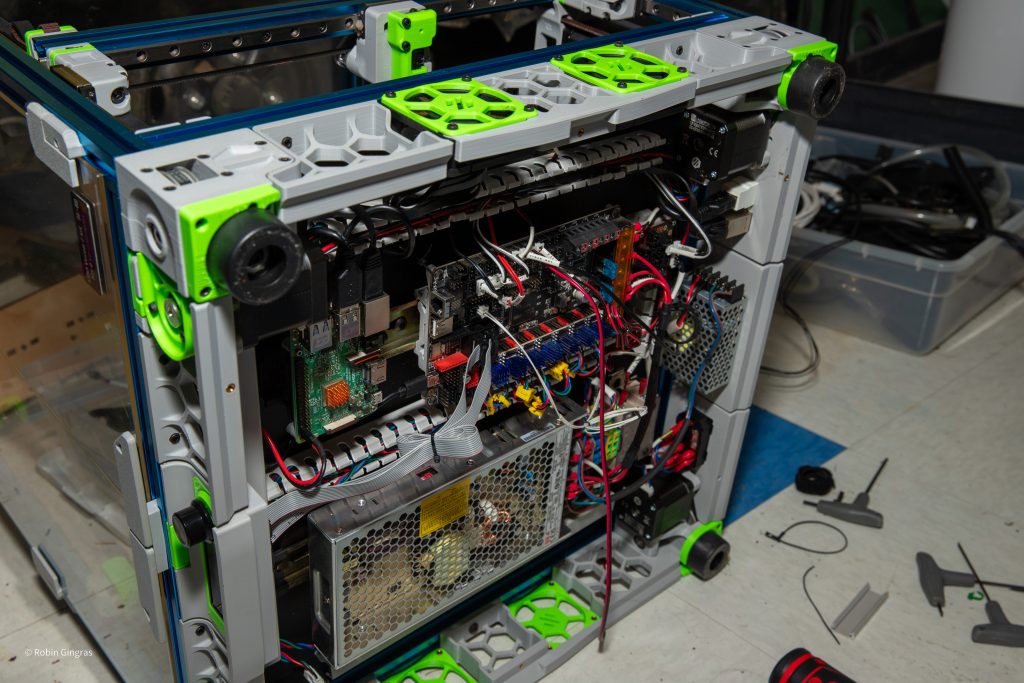

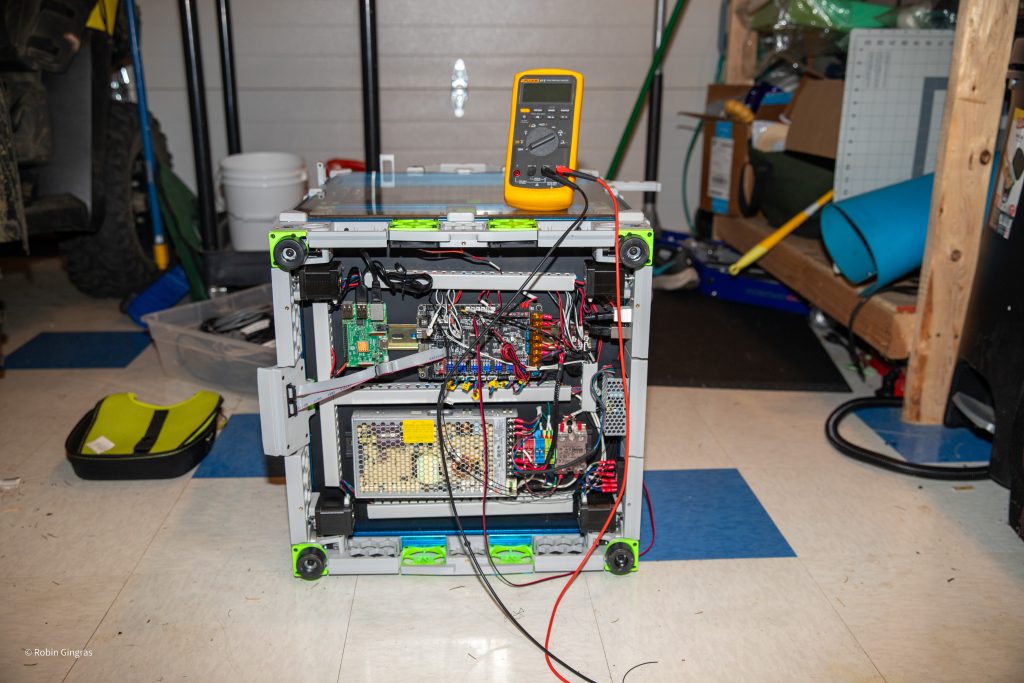

Today’s job was removing the old wiring harness and all the connections on the bottom of the machine that won’t be needed once the CAN toolhead is installed. The entire toolhead (part fan, heater fan, heater, LEDs, probe and stepper will all be connected to the toolhead PCB (Mellow Fly SB2040) and then to the main controller via CAN.

Luckily everything else looks great and I don’t feel the need to do any cleanup/modifications except securing a few wires that were added while the machine was in it’s place. Now we wait for parts…

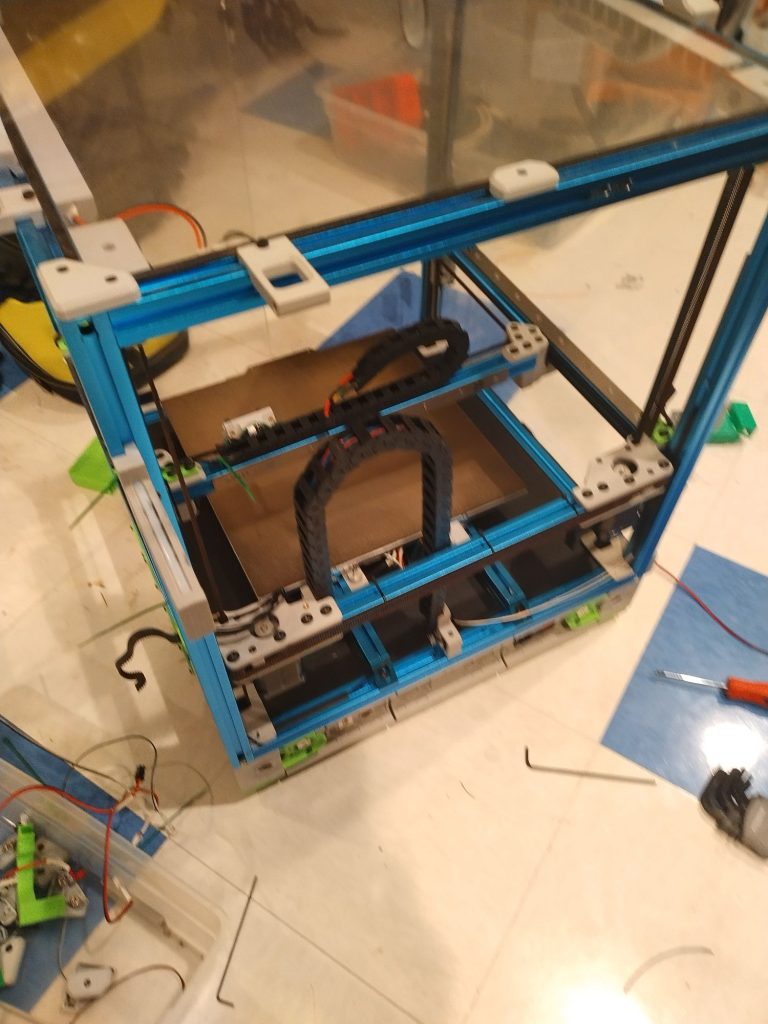

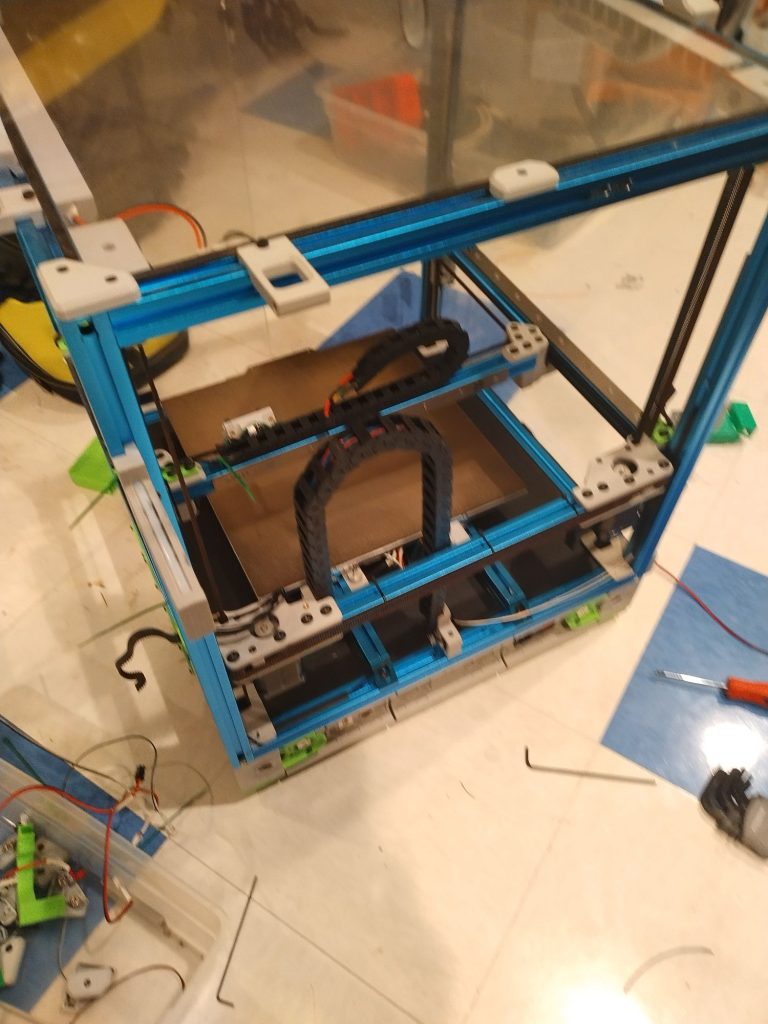

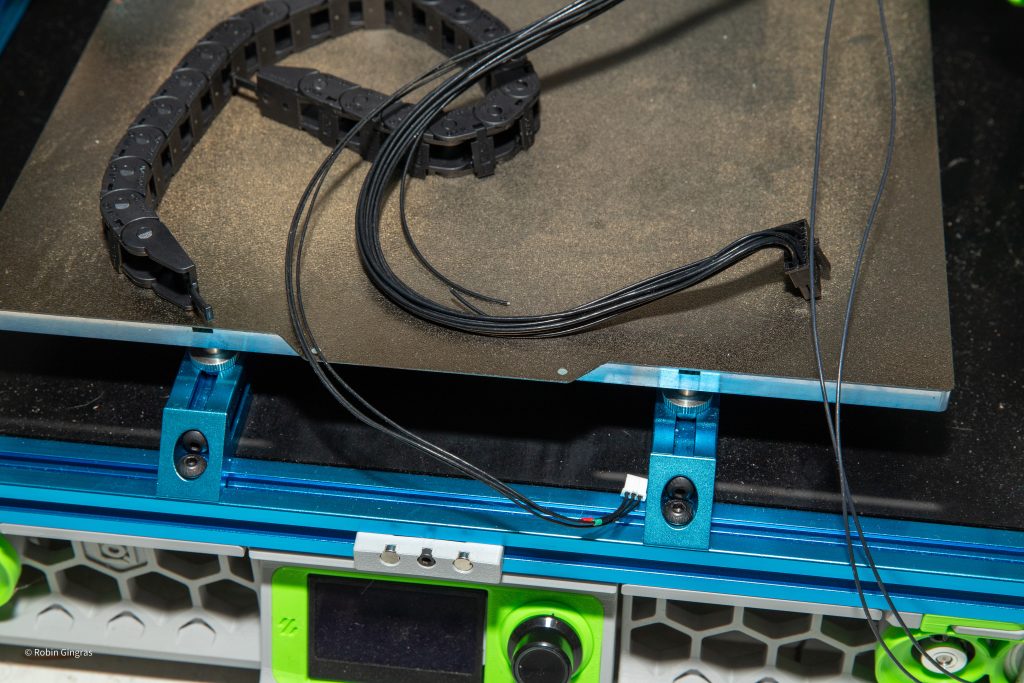

I’ve begun tearing out the old wiring harness on #3667. First the right-hand side panel comes off, then the extruder, then the cable chains:

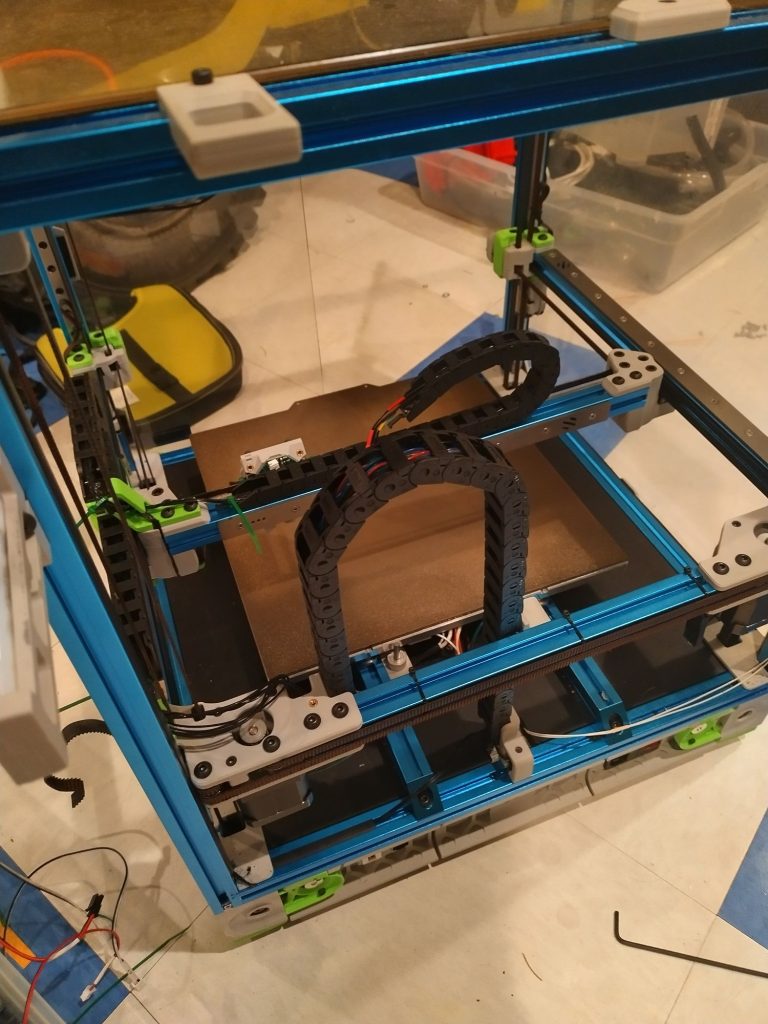

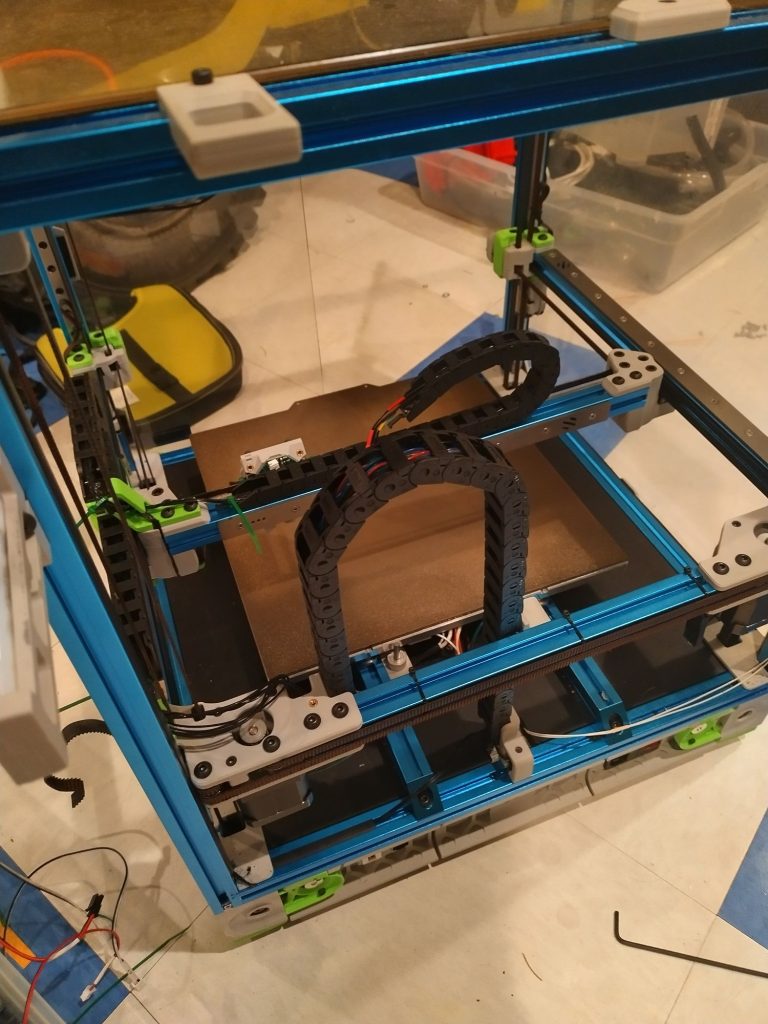

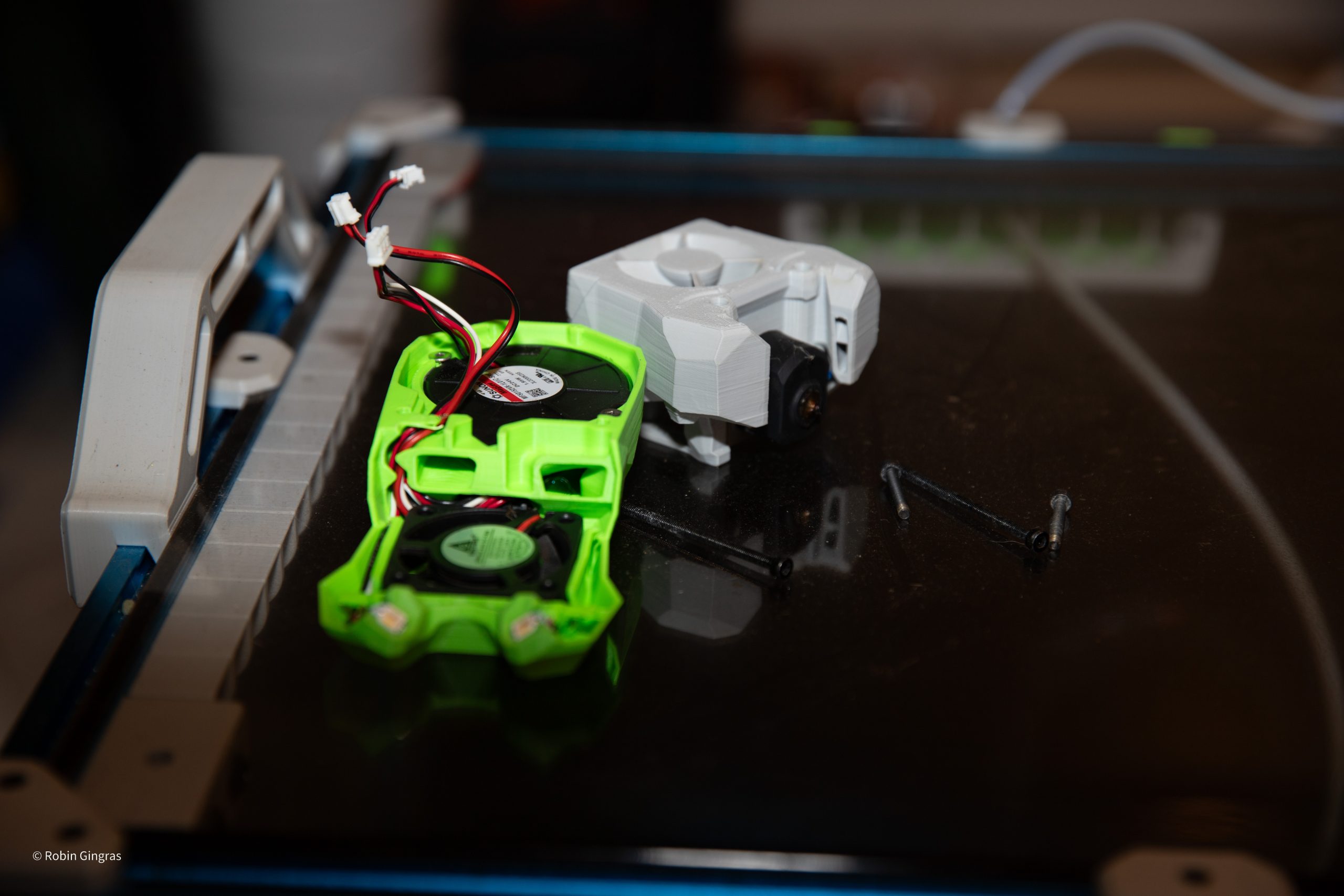

It didn’t take long for me to find the broken wire, it was in the x-chain close to the toolhead:

Next step is to finish removing the z-chain and then pull the wiring harness completely out of the machine. After that I plan to upgrade the Pi OS and Klipper. By then the parts for CAN should be here.

Looking at Voron #3667 and it did not take very long to find that one of the stepper motor lines has a discontinuity. Somewhere.

Rather than try to replace one wire, the logical choice would be to replace the entire toolhead harness, since it’s likely to have another break at some point. However, replacing the whole wire harness would be a huge pain, and more costly than going CAN on account of the expensive wire you need.

So, I’ve already placed an order for a Mellow Fly SB4020 CAN toolhead board and the accompanying wire harness. At first I was apprehensive about going CAN just due to the scattered nature of information I was finding, but I think I’ve managed to find enough quality procedures to do each part of the upgrade.

The first step will be to remove the old wiring harness in preparation for CAN. I will be sticking with the cable chains for now, but I’m currently researching the umbilical that I can always add later.

After replacing a stepper motor driver and a stepper motor, the problem with the extruder motor still exists. That leaves one remaining suspect which is a broken wire in the wire harness to the print head. Now the printer is on the floor awaiting repairs. I may use the opportunity to upgrade to a CAN system, so I’m shopping for a kit to see what the cost will be. A CAN system has been the eventual plan anyways, so now may be the right time.

After replacing both a stepper motor driver and the extruder motor itself, the problem still persists. Looks like there may be a broken wire in the wire harness. I’ve got the printer on the floor on it’s side ready to test the wires tomorrow. If I do find a broken wire, it may mean time to replace the whole wiring harness, which would be a big task. I’m actually considering upgrading to a CAN-bus setup. Now would be the time.